Aims & Scope

Journal of 3D Printing and Applications (J3DPA) publishes peer-reviewed research on additive manufacturing processes, materials science, fabrication methods, and engineering applications of 3D printing technologies across industrial sectors.

Additive Manufacturing Materials Science Process Engineering Quality Control Industrial Applications

Core Research Domains

Additive Manufacturing Processes Tier 1

- Fused deposition modeling (FDM) and material extrusion

- Stereolithography (SLA) and vat photopolymerization

- Selective laser sintering (SLS) and powder bed fusion

- Binder jetting and material jetting technologies

- Direct energy deposition and metal additive manufacturing

- Process parameter optimization and control systems

Typical Fit Example

"Optimization of laser power and scan speed parameters in selective laser melting of Ti-6Al-4V alloy for aerospace components"

Materials Science & Engineering Tier 1

- Polymer materials: thermoplastics, thermosets, elastomers

- Metal alloys: titanium, aluminum, steel, nickel-based superalloys

- Ceramic materials and composite systems

- Bio-based and sustainable printing materials

- Material characterization: mechanical, thermal, microstructural

- Multi-material systems and functionally graded materials

Typical Fit Example

"Mechanical property characterization of carbon fiber reinforced polymer composites fabricated via continuous fiber 3D printing"

Design & Computational Methods Tier 1

- Computer-aided design (CAD) for additive manufacturing

- Topology optimization and generative design algorithms

- Computational modeling and finite element analysis

- 3D scanning, reconstruction, and reverse engineering

- Simulation of printing processes and defect prediction

- Design for additive manufacturing (DfAM) methodologies

Typical Fit Example

"Topology optimization framework for lattice structures in metal additive manufacturing with overhang constraints"

Quality Control & Metrology Tier 1

- Dimensional accuracy and geometric tolerance analysis

- In-situ monitoring and process control systems

- Non-destructive testing and defect detection

- Surface finish characterization and post-processing

- Standardization and certification protocols

- Quality assurance frameworks for industrial adoption

Typical Fit Example

"Real-time thermal monitoring system for porosity detection in laser powder bed fusion using infrared thermography"

Secondary Focus Areas

Industrial Applications

- Aerospace: lightweight structures, engine components

- Automotive: rapid prototyping, tooling, end-use parts

- Energy: turbine components, heat exchangers

- Construction: architectural elements, building components

- Electronics: printed circuit boards, enclosures

- Consumer goods: customized products, manufacturing tools

Manufacturing Systems

- Supply chain integration and distributed manufacturing

- Mass customization and on-demand production

- Hybrid manufacturing: additive-subtractive integration

- Digital twin technologies for process optimization

- Industry 4.0 and smart manufacturing systems

- Economic analysis and cost modeling

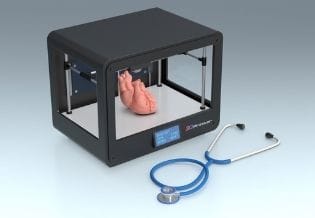

Bioprinting & Biomaterials

- Biocompatible material development and characterization

- Scaffold fabrication for tissue engineering research

- Bioprinting process development and optimization

- Material-cell interaction studies

- Manufacturing of anatomical models for surgical planning

- Prosthetic and orthotic device fabrication methods

Sustainability & Innovation

- Recycled and bio-based feedstock materials

- Energy efficiency in additive manufacturing

- Waste reduction and circular economy approaches

- Life cycle assessment of 3D printing processes

- Environmental impact analysis

- Sustainable material development

Emerging Research Frontiers

Selective Consideration Areas

AI & Machine Learning

- Machine learning for process parameter optimization

- Defect prediction using neural networks

- Computer vision for quality inspection

- Generative design algorithms

Advanced Functional Printing

- 4D printing and shape-memory materials

- Printed electronics and sensors

- Multi-functional material systems

- Food printing technology and materials

Editorial Note: Submissions in emerging areas undergo additional editorial review to ensure alignment with manufacturing science focus. Manuscripts must emphasize process development, material characterization, or engineering applications rather than end-use outcomes.

Article Types & Priorities

Priority 1: Fast-Track Review Typical decision: 21 days

Original Research Articles Systematic Reviews & Meta-Analyses Review Articles & Literature Reviews Methods & Protocols Technical Notes Short Communications & Rapid Communications Data Notes & Data Reports

Priority 2: Standard Review Typical decision: 21 days

Case Reports & Case Studies Perspectives & Commentaries Opinion Pieces Editorials Letters to the Editor Conference Proceedings Theses Clinical Trials Book Reviews

Rarely Considered High editorial bar

Editorial Standards & Requirements

Reporting Guidelines

- ASTM standards for additive manufacturing (F2792, F3049)

- ISO/ASTM 52900 series for terminology and processes

- Material characterization per ASTM D638, E8, E9

- Statistical reporting per APA or journal guidelines

- ARRIVE guidelines for animal studies (if applicable)

Data & Reproducibility

- Process parameters must be fully disclosed

- Material specifications and supplier information required

- CAD files and G-code sharing encouraged

- Raw data deposition in public repositories recommended

- Replication protocols for experimental studies

Ethics & Compliance

- IRB approval for human subjects research

- IACUC approval for animal studies

- Conflict of interest disclosure required

- Funding source transparency

- Adherence to COPE ethical guidelines

Preprint & Prior Publication

- Preprints on arXiv, bioRxiv accepted

- Conference abstracts do not preclude submission

- Prior publication in non-peer-reviewed venues allowed

- Duplicate submission prohibited

- Preprint DOI must be disclosed at submission

Decision Metrics

Journal Performance Indicators

21 days Time to First Decision

53% Acceptance Rate

3 days Acceptance to Publication

40 days Submission to Publication

Ready to Submit?

If your research aligns with our manufacturing science focus and meets our editorial standards, we invite you to submit your manuscript for peer review.

Contact Editorial Office